Do you manufacture?

Do you have throughput issues?

Do you have re-work issues?

Do you have defects?

Do you have scrap?

Do you have downtime issue?

Do you have reactive analytics?

If you answered yes to any of the above, join thousands of other manufacturing companies struggling with the same thing. Industry 4.0 is not about more data being the answer.

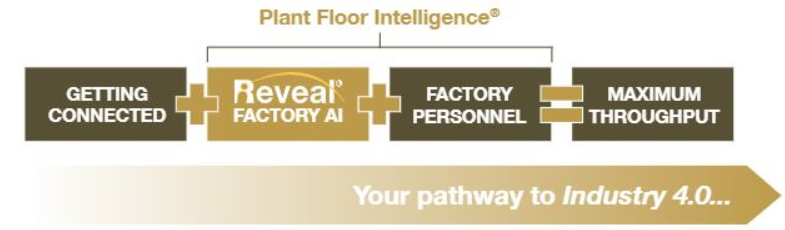

So, what does this mean? There is a myth that data is all you need to enter the next phase of manufacturing. Data must be activated through the marriage of artificial intelligence (AI) and human intelligence; the factory workforce. Activating your data is the key to next-gen proactive factory control. This is done by connecting Data + AI + Factory Personnel = Maximum Throughput.

Tools such as REVEAL Plant Floor Intelligence created by Trumble Inc does just that. Trumble’s CEO and visionary Jeff Trumble spent 15 years on the factory floor then another 15 years in management putting out fires, reacting to issues after they occurred and after negative production and financial impacts we suffered. REVEAL Plant Floor Intelligence was born out of this frustration.

Plant Floor Intelligence (PFI ) is a new manufacturing strategy offering PROACTIVE CONTROL of factory processes by mobilizing the factory floor workforce, the people at the source that can make the biggest impact on scrap, defective parts, throughput, and first-time capability quickly and effectively. How you ask? This group of workers are stereotypically have little or no statistical or analytical backgrounds and are not typically engineers so how is this possible?

With tools such as REVEAL , the plant floor worker community goes from underutilized group to quickly becoming an army of empowered problem solvers, experts in manufacturing proactive control, and plant floor hero’s, all while saving manufacturing companies millions of dollars in decreased defects, scrap, and machine downtime thus increasing productivity, and first time yield.

REVEAL factory AI monitors the entire manufacturing value-stream 24/7 and alerts the workforce to take action before defects occur resulting in a paradigm shift from reactive to proactive. Wait, what? Proactive control, is that even possible? Yes, it is! This tool mines data 24/7 automatically and analyzes trends continuously for threats to manufacturing throughput and automatically sends real-time alerts when corrective actions is required, taking the noise out of the system allowing you to focus on the what’s important. No data-mining skills required. No knowledge of statistics is required. The tool is designed to empower the entire factory floor workforce, is designed to eliminate hours and hours of analysis and statistics putting the information at the fingertips of engineers, operations, management. Automatically calculates COPQ, Sigma Level, FTC/FTY by department, by line, by previous day, week, bi-weekly, monthly or custom date range. Something for every level of manufacturing.

So the question is would you rather continue the way it’s been done for decades: putting out fires all day long an adding a few more grey hairs along the way or are you ready to make the paradigm shift to proactive control in your plant so that you’ll never miss another one of your kids sporting events again?!

Ask the REVEAL Solutions team how they can help you obtain this and make it a reality today.